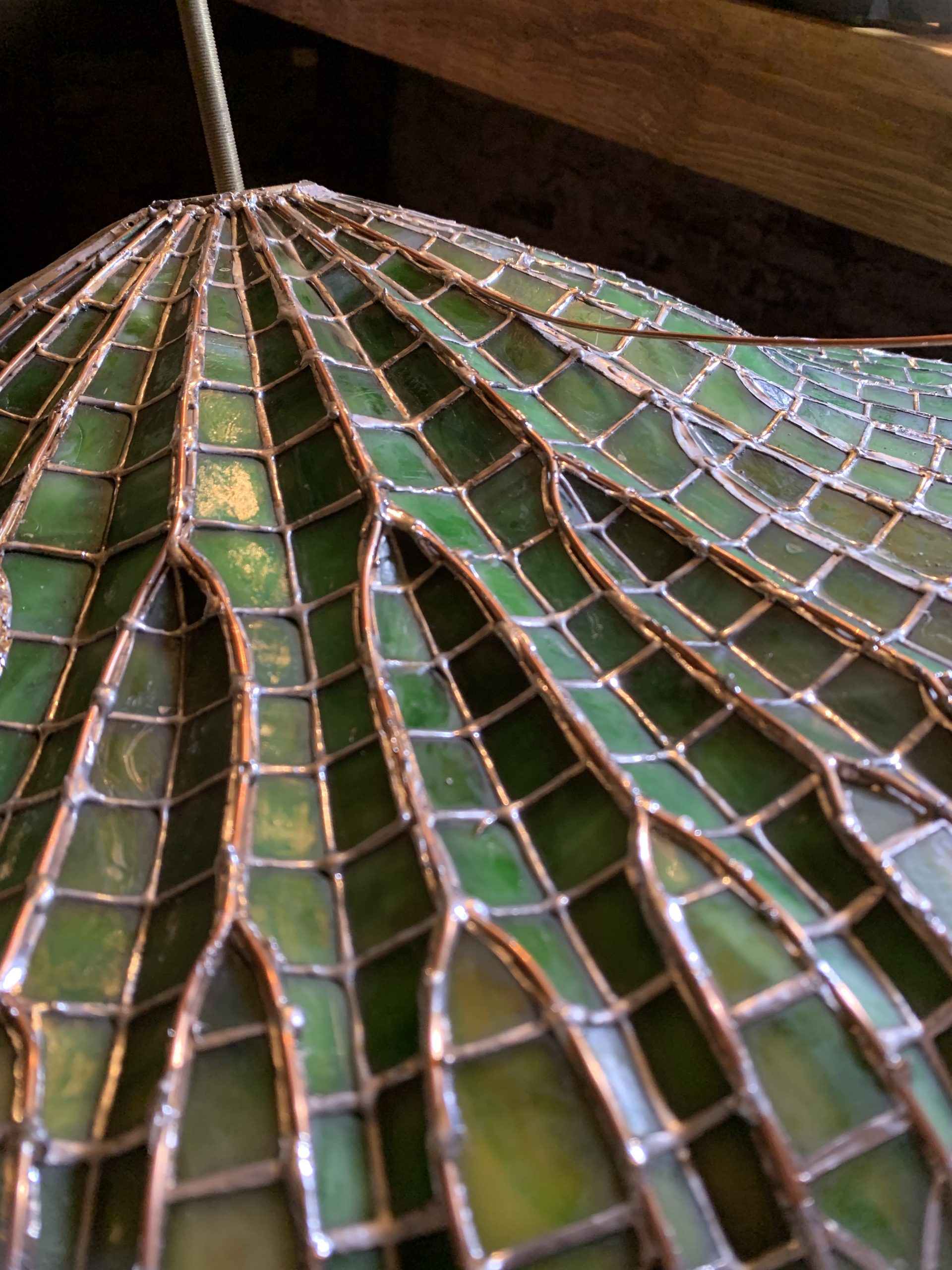

Creating a single Tiffany lamp can take weeks to months, depending on its size, complexity, and the availability of skilled artisans. This extended timeline makes Tiffany lamps high-value art pieces and contributes to their rarity. The design of Tiffany lamps typically incorporates intricate patterns, elaborate motifs, and a wide array of colours and textures. This complexity demands significant artistic skills and attention to detail during the design phase. At Alexandra Tiffany, creating a unique and aesthetically pleasing design that complements the lamp’s shape and size requires meticulous planning and creativity.

The result of creating a Tiffany lamp is a stunning, unique work of art.

Creating a commissioned Tiffany lamp is an intricate process, often taking anywhere from 3 to 9 months.

Selection and Procurement of Quality Materials

Tiffany lamps are renowned for using high-quality stained glass, contributing to their stunning visual appeal. Finding and procuring premium glass with the right colours and opalescent qualities can be challenging. Materials like bronze for lamp bases and fixtures must also be chosen carefully to ensure durability and compatibility with the overall design.

Glass cutting and Grinding

Tiffany lamps are predominantly handcrafted, which means skilled artisans meticulously cut, grind, and assemble each piece of glass on Tiffany lamp molds. This labour-intensive process demands exceptional craftsmanship and can be time-consuming. The glass-cutting process requires precision and accuracy to achieve the desired shapes and fit them seamlessly together. Every glass piece then needs to be hand-grind in order to smooth out the edges so that the copper foil, a technique that paved the way for Louis Comfort Tiffany’s famous Tiffany lamps, can stick better on the glass and help create strong joints between glass pieces.

Glass grinding and preparation.

Copper foiling and Soldering

After the individual pieces of glass are cut and ground, they are then wrapped with copper foil around the edges. This allows the pieces to be joined using soldering, requiring expertise to create a sturdy and visually appealing bond between the glass pieces.

Each piece of glass is carefully hand-foiled to create intricate solder lines.

Soldering a Tiffany lamp takes 2 to 4 weeks. Due to the non-flat surface of the Tiffany lamp shades and the fact that gravity compels 800-degree molten solder to run downhill, the shade must be regularly repositioned to ensure a proper bead line. In the case of the 25″ Mandarin Lotus lamp, each fold peak is accentuated with hand-crafted copper wires to add reinforcement to the lamp shade and highlight the three-dimensional aspect of the design, a true painstaking process.

Stunning and timeless work of art that reflects the beauty and skill of the Tiffany lamp tradition.

The copper wire hand-soldered to the bottom of a Tiffany lamp not only strengthens the shade but also smoothes out the edge, giving them a nice aesthetic lower edge.

The irregular lower edge is finished with a half-round copper wire.

Patina and Quality inspection

To enhance the lamp’s appearance and create an aged, antique look, a patina is applied to the solder lines. Achieving the desired patina color and texture identical to that employed by Tiffany Studios requires skill and experience.

Before proceeding with any final touches, the entire lamp undergoes a thorough inspection. Skilled artisans examine the lamp from every angle to identify any imperfections or inconsistencies that need to be addressed. Some excess solder may have accumulated in certain areas during the soldering process. The artisans carefully clean and smooth these solder joints to create a seamless and visually appealing appearance.

25″ Mandarin Lotus Leaf Tiffany lamp being examined from every angle to identify any imperfections or inconsistencies that need to be addressed.

Once all the final touches are completed, the lamp undergoes another round of cleaning to remove any dust or debris. It then undergoes a final inspection to ensure that every detail meets the highest standards.

The glass pieces’ uneven or rough edges are carefully trimmed and smoothed out. This ensures all glass elements fit perfectly together and contribute to the lamp’s aesthetics. Each glass piece is meticulously polished to enhance its shine and remove any fingerprints or smudges acquired during assembly. This step is essential to achieve a flawless and radiant finish.